Die Casting Mold Design and Development

Effective die casting can produce thousands of high-quality molded casts in a relatively short amount of time while utilizing a single mold. This highly economical and cost-effective approach to die casting injection molding can produce casts with uniform quality and high degrees of accuracy. Die casting mold development provides premium quality, near “net shape” parts at a price point that is extremely cost-effective.

The machining process of die-cast parts must be considered well before any order for the tooling is released. A careful evaluation of machined requirements can lead to redesign for net shape die-casting or near-net shape with a reduced number of operations.

Contact SKS Die Casting for more information regarding die casting mold design development or Request a Quote today.

Die Casting Injection Molding Services

SKS's first-class team of in-house engineers can oversee all aspects of tooling and the injection process. We can produce thousands of high-quality molded casts in a short amount of time.

Die Casting Mold Development

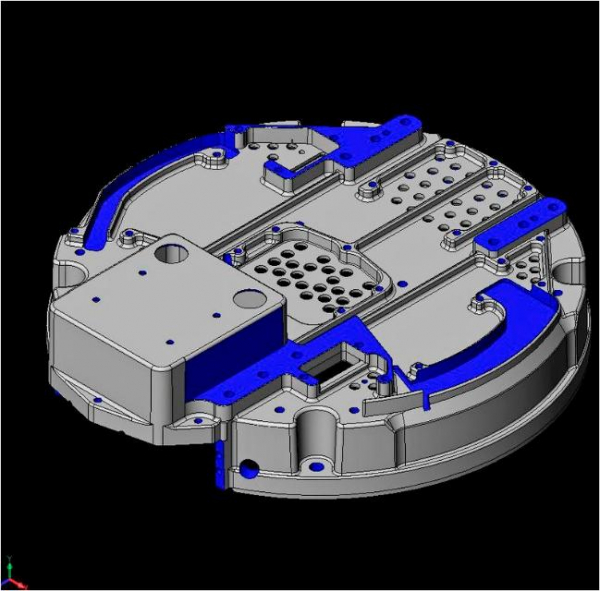

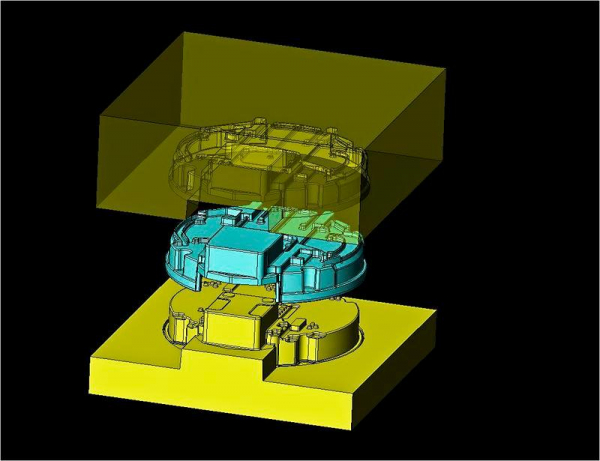

The Die Casting Mold Development Process

Die casting is an automated process in which liquid metal is pressed into a mold under extreme pressure at a high rate of speed. The die casting mold design process is highly suitable for mass production of components and is generally used with alloys with a lower melting point. Since permanent metal molds are utilized for the die casting mold design process, producing large and complex components with low wall thicknesses is possible.

What are Die Casting Molds?

The molds utilized in the die casting mold design process are constructed from premium, heat-resistant steel grades. The molds are halved to form a cavity where the liquid metal is pressed during the casting process. A die casting mold is so strong that over a million parts can generally be created with a single mold. However, the actual life of the mold will solely depend on the die casting materials used.

Die Casting Mold Development Advantages

Die casting utilizes non-ferrous metals (such as aluminum alloys or zinc alloys) to manufacture components. The chosen alloy for an application depends on budget, weight, and material properties. Other benefits associated with the use of die casting mold design include:

- High thermal conductivity

- High electrical conductivity

- Good processing properties

- Excellent EMI/ RFI isolation

- High corrosion resistance

- High strength and hardness

Why Choose SKS for Your Die Cast Injection Molding & Mold Development Service Needs?

SKS Die Casting works closely with customers to explore assembly and installation solutions for their custom die casting mold design needs, including those with specific assembly and installation requirements. We also provide a range of mold material options, including premium grade H13, Uddeholm Orvar, and Dievar, to support your project needs. Additional benefits of choosing SKS include:

- First-class engineering

- In-house die cast tool design

- Injection process parameter development

- Minimum and maximum wall thicknesses

- Flow simulation

- Draft, radii & filets

- Establishing machining stock

- Domestic & overseas tooling suppliers

Contact SKS for your Die Casting Mold Design & Development Needs Today

In the market for die casting mold development and design to meet your project specifications? Contact us for more information regarding our custom die casting and injection molding service options, or request a quote for direct pricing today.