Hot Chamber Die Casting Services

Hot chamber die-casting is a method of die manufacturing for metals with low melting points, like zinc. The molten metal is forced into the die mold, where it quickly solidifies into the proper shape and is ejected, fully completed. This form of die-casting is consistent, quick, and accurate.

Cold chamber die casting is an additional die-forming method with a similar process. While SKS does not provide hot chamber services, we offer superior cold chamber die-casting services for various industries and requirements. Contact us today for more information on our cold chamber die-casting services.

Hot Chamber Die Casting Process

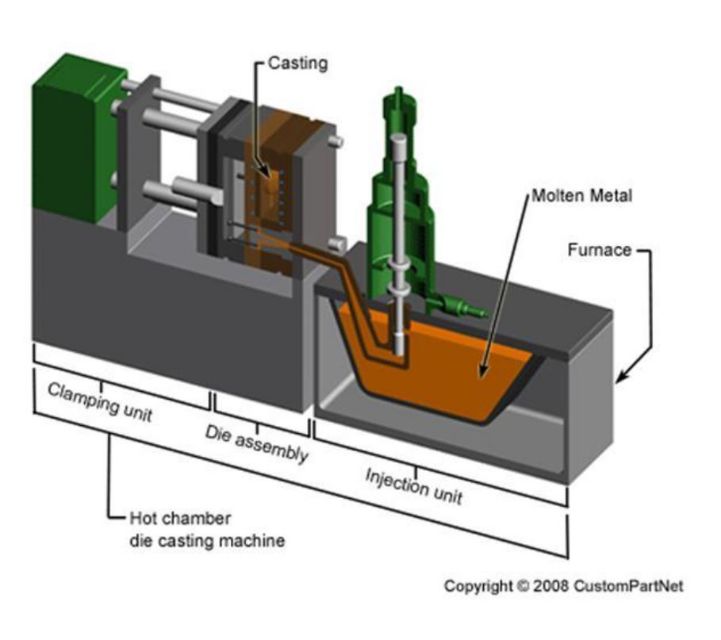

Hot chamber die casting begins with molten metal, typically zinc, magnesium, or other alloys with low melting points. The furnace containing the melted metal is attached to the casting machine by a feeding system known as the “gooseneck.” To begin the die-casting process, an injection plunger forces the liquid metal through the gooseneck and into the die cavity.

Away from the furnace, the molten metal in the cast quickly solidifies in shape. After the metal has solidified, the plunger is withdrawn, and the machine opens and ejects the completed die. The process begins again with the plunger forcing more molten metal into the die cast.

Hot Chamber Die Casting Advantages

Hot chamber die casting is widely used for high production levels of dies created from materials with low melting points. The rapid cooling of the metals leads to fast cycle times and quick operation. Additional benefits include:

- Automated processing

- Consistent production

- Versatility and precision

- Intricate detailing

- Expanded die lifespan

- Waste reduction

- Design efficiencies

Cold Chamber Die Casting

Although SKS does not offer hot chamber die-casting services, we do proudly offer cold chamber die-casting services. Cold chamber processing utilizes a similar production process to hot chamber die casting. The most significant difference is that the metals used for cold casting, such as aluminum, typically have much higher melting points. As such, these metals must be heated separately from the casting machine. They are poured into the casting machine with a ladle, then plunged into the die.

These metals are typically stronger than materials with lower melting points. They offer increased hardness and durability to the die, making cold casting a beneficial solution for demanding applications.

Die Casting Services

Along with Cold Chamber Die Casting, we offer additional die-casting services for a variety of applications.

Aluminum die casting is commonly employed for aluminum’s many advantages. Aluminum parts are lightweight and strong, with excellent corrosion resistance and superior surface finishes.

The team at SKS performs high-quality die-casting mold design and development. This allows dies to be custom-crafted with specific requirements and unique designs for individual applications.

With a variety of die-casting processes, our additional die services are sure to meet or exceed your requirements.

SKS Provides Superior Custom Die Casting

With advanced custom die-casting services, SKS is your superior resource for all industrial die-casting needs. Contact us today, and let us determine the best solution for you.