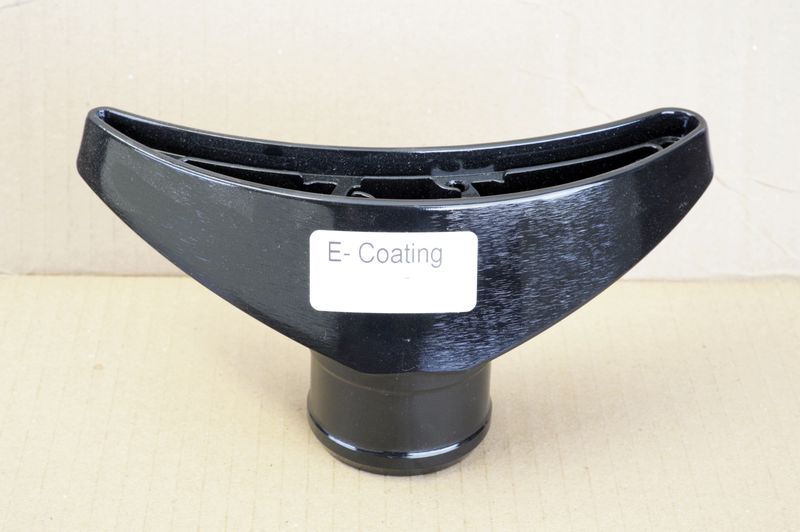

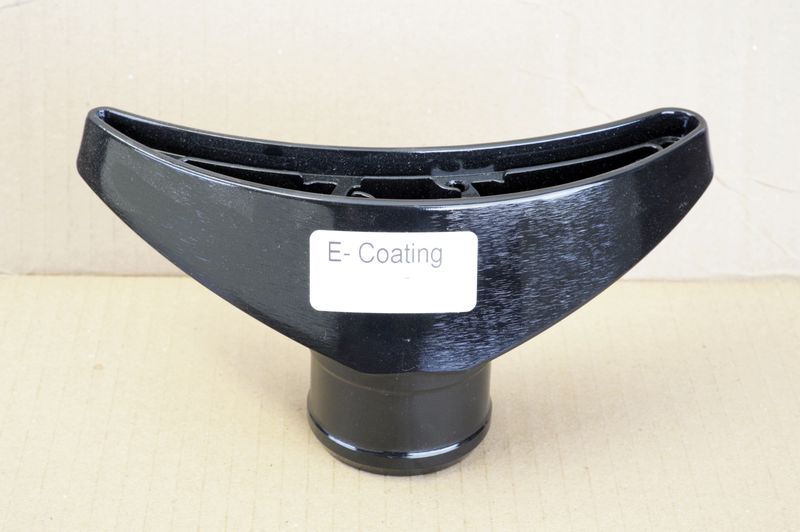

Electrostatic Coating (E-Coating) Surface Finish for Die Cast Parts

Electrostatic coating is a manufacturing process that employs charged particles to more efficiently paint a workpiece. Paint, in the form of either powdered particles or atomized liquid, is initially projected towards a conductive workpiece using normal spraying methods and is then accelerated toward the workpiece by a powerful electrostatic charge.

An addition to the electrostatic coating (or e-coating) process is dipping electrically conductive parts into a tank of paint that is then electrostatically charged. The ionic bond of the paint to the metal creates the paint coating, in which its thickness is directly proportional to the length of time the parts are left in the tank and the time the charge remains active. Once the parts are removed from the paint tank, they are rinsed off to remove any residual paint that is not ionically bonded, leaving a thin film of electrostatically bonded paint on the surface of the part.

Electrostatic Coating Process Characteristics

- Uses a high voltage electrostatic charge which is applied to both the Aluminum die casting component and the sprayer mechanism

- Uses 95% of sprayed paint due to reduced over-spray and better wrap-around

- Paint materials can be liquid

- The process can be either automatic or manual

- The coated components are usually baked after coated

- The coating color is restricted to either black or white.

- The baked-on paint adheres extremely well and is difficult to remove without aggressive means of removal.

Contact SKS Die Casting for more information on our Electrostatic Coating or Request a Quote today.

SKS is your premier manufacturing source for electrostatic coating since 1945.